Yeasts are the living stars of the beer brewing process. Their work remained a secret for hundreds of years of brewing, but once brewers discovered their microorganism partners, they learned to use different yeasts’ characteristics to their advantage.

Yeasts are eukaryotic microorganisms, mostly unicellular, and vary largely in size from about 2 µm in diameter to 40 µm. They are classified in the kingdom Fungi, and have diversified to approximately 1500 different species. For the most part, yeasts reproduce asexually through mitosis, and often new yeasts may simply form as an outgrowth of existing yeast through “budding.”

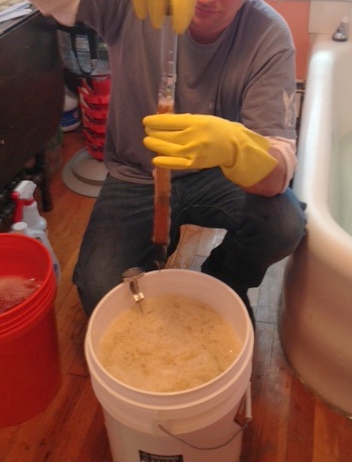

The work that yeasts performed secretly for so long in the brewing process is called fermentation. It is the process by which they convert carbohydrates (sugars from the grains) to carbon dioxide and alcohols. Historically, brewers recognized that fermentation took place, but they did not understand the details of the underlying mechanism. Beer was exposed to the open air, which allowed natural yeast and bacteria to “infect” the beer, consuming the sugars and producing alcohols. One natural yeast is the Brettanomyces Lambicus strain, which produces sour beers descended from the lambic traditions of Belgian brewing.

Scientists in the 1800s began learning more about yeasts’ role in the environment in general as well as in brewing. In 1837, Theodore Schwann showed that yeast was alive, and by 1860, Louis Pasteur was able to connect yeasts to the fermentation process. He demonstrated that yeasts exposed to oxygen simply multiply, but when deprived of oxygen, cause a fermentation. Pasteur invented pasteurization to kill yeast, thus halting fermentation, which allowed more control over a number of food and drink production processes. Pasteurization was applied first to wine in 1864 at the request of Emperor Napoleon III to save his ailing wine industry, and about a decade later to beer (Pasteur authored his Etudes sur la Bière in 1876).

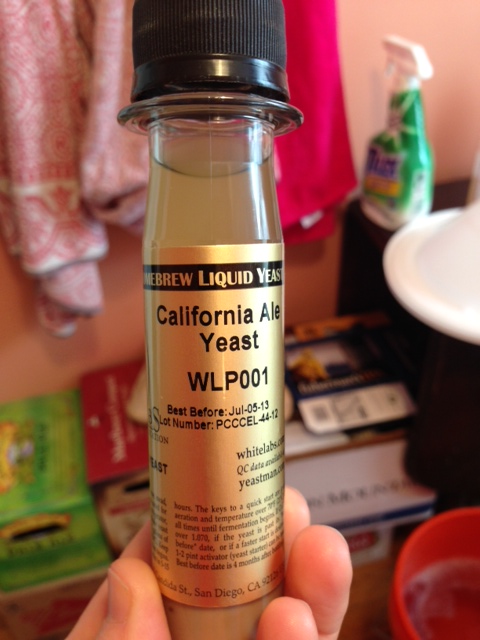

Later, brewers noted that the two main types of beer yeast are ale yeast (the “top-fermenting” type, Saccharomyces cerevisiae) and lager yeast (the “bottom-fermenting” type, Saccharomyces uvarum). The former operate at temperatures ranging from 10 to 25°C and rise to the surface during fermentation to create a thick yeast head. The latter work best at temperatures ranging from 7 to 15°C, and tend to settle at the bottom of the fermenter as their work progresses.

Today, brewers take advantage of yeast by-products in addition to alcohol, which impart much of the flavor and aroma on beer. Examples of these flavor compounds include acetaldehyde (green apple), esters (fruit), diacetyl (butterscotch), 2,3-pentanedione (honey), organic acids (sour or salty), fatty acids (soap), and dimethyl sulfide (cooked sweet corn). Brewers choose particular yeasts for their fermentation processes based on these byproducts, according to their desired aromatic and flavor profiles for the beers. For instance, German Hefeweizens often have distinct hints of banana courtesy of isoamyl acetate, the same ester found in abundance in one of the most popular fruits on Earth.

Next time you appreciate a good beer, take a moment to consider all the hard work accomplished by the yeasts, and imagine which ones were used to create the particular profile of the beer. They worked unappreciated for so long, so it’s up to us to celebrate their accomplishments – after all, they have supported networking and the creation of social connections for centuries.